Contract Manufacturing for Pharma and Diagnostics

A key challenge that many diagnostics and pharma developers face is manufacturing high-quality lyophilized or liquid products in time for rapid production schedules. Although achieving this involves managing a range of variables, framing your contract manufacturing projects on a robust foundation of lyophilization expertise is one of the most important factors.

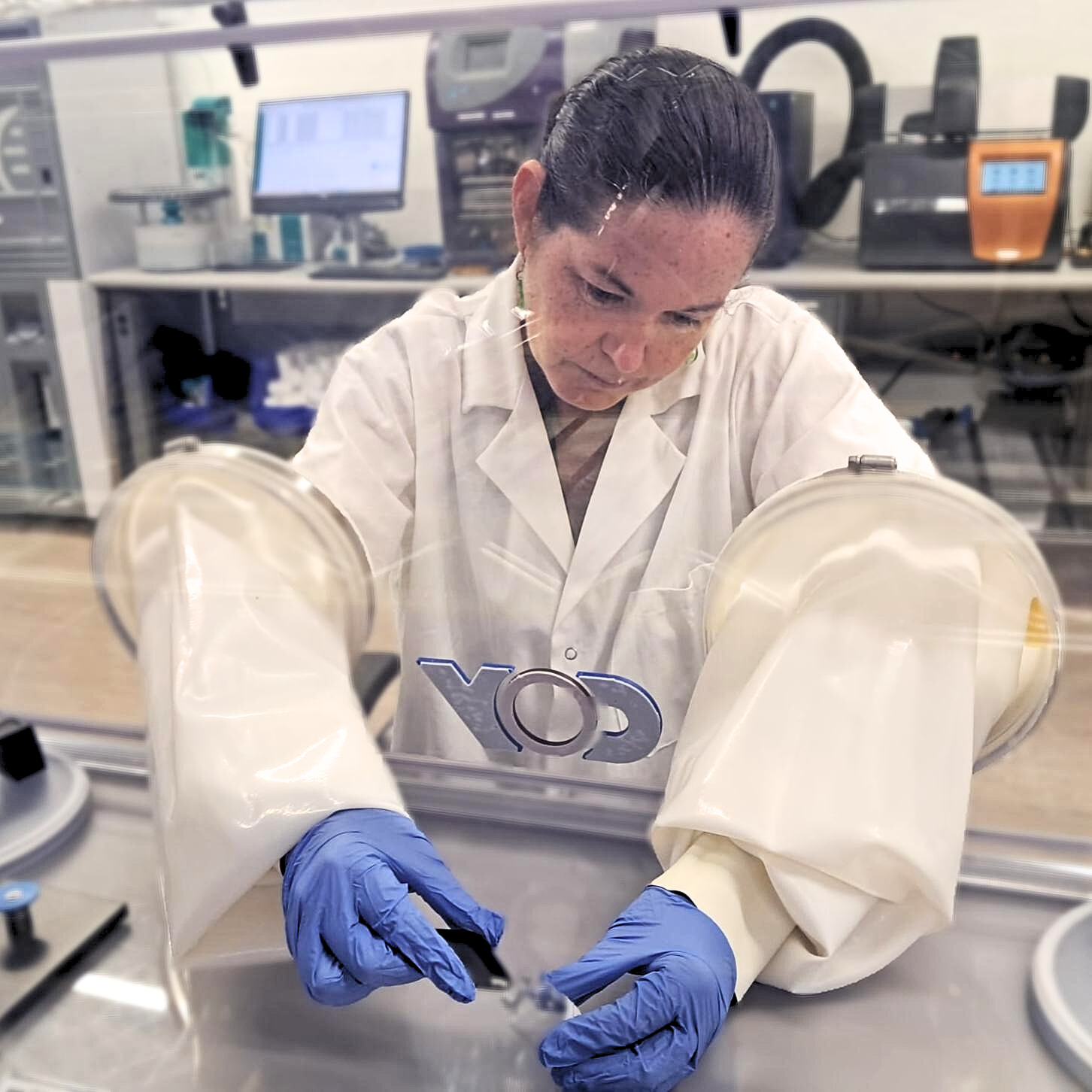

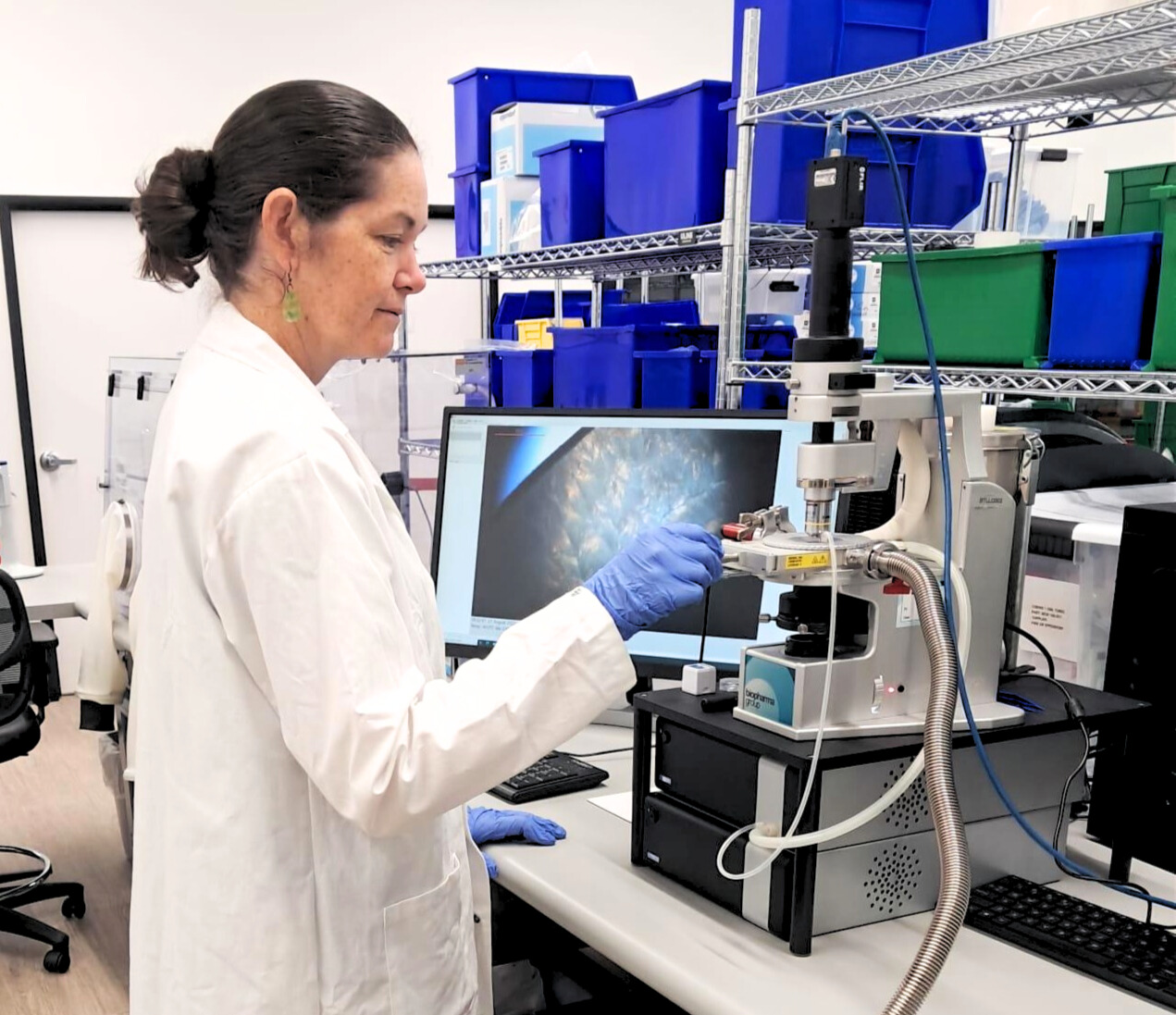

At Biopharma Technology LLC, our expert scientific team applies their deep technical understanding of lyophilized products to your manufacturing projects, providing full assurance for their successful and timely delivery. Working from our advanced lab facility in Carlsbad, California, we perform all steps in house – including product assessment and troubleshooting, scale up and technical transfer up to manufacturing. Our facility is ISO 9001 and ISO 13485 accredited, so regulatory compliance is built in from the outset of your project.

Whether you need to manufacture diagnostic reagents, lyobeads or other lyophilized formulations, we tailor our manufacturing approach to your specific requirements to give you reliable, reproducible batches every time. Our extensive freeze-drying expertise enables us to quickly adapt to any formulation changes, enabling us to deliver quality diagnostics or pharma batches without delays.

When working with Biopharma Technology LLC, you retain full ownership of your intellectual property (IP) throughout the project. This means that you have control over its outputs and innovations, allowing you to implement these into your operations, audits, business strategy and brand identity.

How Biopharma Technology LLC Manufactures Freeze-Dried Diagnostic Products

- Product assessment

Every project begins with a detailed assessment of your diagnostic product. We evaluate your formulation and lyophilization requirements to understand the unique demands of your assay or reagent using our freeze-drying microscope (FDM), Lyostat 5, and our frozen state analyzer, Lyotherm 3. Occurring before lyophilization, this step ensures we can optimize your product’s downstream manufacturing process for stability, performance, and efficiency.

During this phase, differential scanning calorimetry (mDSC), coulometric Karl Fischer analysis and MicroPress testing are also completed to ensure product quality. - Troubleshooting

Biopharma Technology LLC’s expert team applies decades of lyophilization, aka freeze-drying, experience to fine-tune your product’s manufacturing approach, helping to eliminate variables that could compromise product quality and delivery timescales. - Scale-up and tech transfer

Once the manufacturing approach is optimized, Biopharma Technology LLC scales this up for tech transfer, while fully documenting the process along the way. Our advanced equipment range, and close collaboration with your team, ensure seamless tech transfer from R&D to production. - Small-batch manufacturing

We specialize in small-batch manufacturing for lyophilized or liquid diagnostics products. This makes our services ideal for early-stage launches, pilot production, and clinical studies. Because all production happens in our Carlsbad facility, we can offer fast turnaround while maintaining full traceability and quality oversight. - Packing, kitting, and shipping

Biopharma Technology LLC offers complete diagnostics kitting and logistics services, including custom packaging, labeling, and shipping solutions across the US. This approach reduces complexity for our customers and ensures your product is ready for the next phase of its launch.

How Biopharma Technology LLC Supports Manufacturing for Lyophilized Pharmaceutical Products

- Troubleshooting

We conduct a deep technical review of your pharmaceutical formulation and freeze-drying challenges. Specifically, we use our Lyostat 5 and Lyotherm 3 technology to verify the performance of your product across a wide range of variables, helping to ensure a seamless and efficient manufacturing process. Dry-state characterization techniques are also completed during this step, including mDSC, coulometric Karl Fischer analysis and MicroPress testing. - Scale-up and tech transfer support and assistance

Biopharma Technology LLC assists with scale-up planning and tech transfer for lyophilized pharmaceuticals, particularly for clients preparing to transition to pre-clinical scale manufacturing. We generate process data and run small-scale studies to ensure your product performs consistently at larger volumes. - Transfer of master batch record and IP

Once the formulation and its processes are established, we support the transfer of your master batch record (MBR) and intellectual property (IP). These can be transferred to other larger facilities if needed for commercial-scale production. Our documentation meets ISO 9001 and ISO 13485 requirements, helping to simplify regulatory compliance and prepare for scale up.